Introduction

Welding is an art and a science that forms the backbone of many industries. From manufacturing to construction, the ability to join metal components together is crucial. Among the various welding techniques available, Arc Welding stands out due to its versatility and efficiency. Whether you're looking to embark on a career in welding or simply want to learn a new skill, understanding arc welding is essential. This guide aims to be your comprehensive resource, diving deep into various aspects of arc welding while also touching upon related techniques like MIG Welding, TIG Welding, and Plasma Welding.

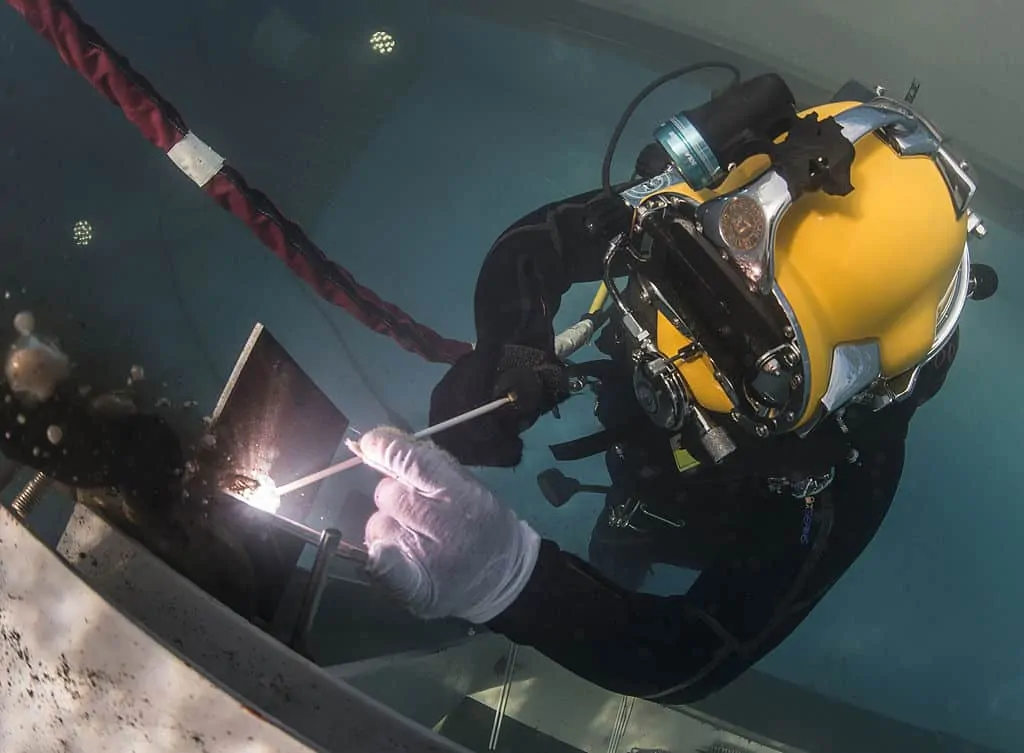

In this extensive article, we'll cover everything from the basics of welding safety to the intricacies of different equipment and methods. So grab your helmet and get ready; let's dive into "A Complete Guide to Arc Welding for New Welders."

What is Arc Welding?

Arc welding is a fusion process that uses an electric arc to melt and join metals together. The arc generates high temperatures—often exceeding 6,500 degrees Fahrenheit—which allows for the melting of base metals as well as filler materials.

How Does Arc Welding Work?

The process operates through the following steps:

Power Source: An electric power supply generates voltage and current. Electrode: A consumable or non-consumable electrode creates an arc between itself and the base metal. Filler Material: If using a consumable electrode, molten material contributes to filling gaps between joined metals. Shielding Gas: In some cases, gas protects the weld pool from contamination.Types of Arc Welding Techniques

Arc welding encompasses various techniques tailored for specific applications:

- Shielded Metal Arc Welding (SMAW) Gas Tungsten Arc Welding (GTAW) Gas Metal Arc Welding (GMAW) Flux-Cored Arc Welding (FCAW)

Essential Equipment for Arc Welding

Having the right equipment is paramount when starting your journey in arc welding.

Welding Machine

The heart of any arc welding setup is the welding machine itself. Choose between AC (Alternating Current) or DC (Direct Current) machines based on your needs.

Protective Gear

Safety should always be your top priority:

- Helmet with UV protection Flame-resistant clothing Gloves Steel-toed boots

Electrodes

Choosing the right electrode type can significantly impact your weld quality.

Work Surface

A sturdy work table made from steel prevents unnecessary movement while you weld.

Basic Principles of Safety in Arc Welding

Safety cannot be overstated when it comes to welding.

Personal Protective Equipment (PPE)

Always wear appropriate PPE such as gloves, goggles, and helmets designed specifically for welding tasks.

Ventilation Requirements

Ensure proper ventilation to avoid harmful fumes; use exhaust fans if necessary.

Fire Safety Measures

Keep fire extinguishers nearby and ensure a clean workspace free from flammable materials.

The Role of MIG and TIG in Metal Fabrication Service

While this guide focuses on arc welding, it's important not to overlook other popular methods like MIG and TIG.

MIG Welding: A Brief Overview

MIG (Metal Inert Gas) welding utilizes a continuous wire feed as an electrode along xpress mobile welding Phoenix with shielding gas.

Benefits of MIG over Arc Welding

Easier technique Faster operation Good for thin materialsTIG Welding: Precision at Its Best

TIG (Tungsten Inert Gas) welding offers higher precision by using a non-consumable tungsten electrode along with filler rods.

When Should You Use TIG?

TIG shines in applications requiring exceptional quality, such as aerospace or pressure vessel fabrication.

Mobile Welding in Phoenix: A Growing Trend

Mobile welding services are becoming increasingly popular due to their convenience.

Advantages of Mobile Services

Time-saving Flexibility Lower overhead costsSpecialized Techniques: Plasma Welding Explained

Plasma welding combines aspects of both TIG and traditional arc methods but offers unique advantages like deeper penetration and faster speeds.

Preparation Steps Before Starting Your First Weld

Preparation is key to successful outcomes in any endeavor—including welding!

1. Gather All Necessary Equipment

Create a checklist so you don’t miss anything crucial.

2. Clean Your Work Area

Ensure there’s ample space free from distractions or hazards.

3: Understanding Different Types of Metals for Welds

Different metals react uniquely during the welding process; knowing these differences helps achieve stronger joints.

| Metal Type | Characteristics | Best Uses | |---------------|----------------------------------|------------------------------| | Steel | Strong, durable | Construction | | Aluminum | Lightweight | Aerospace | | Stainless Steel | Corrosion-resistant | Food processing industries |

4: Practice Makes Perfect: Mock-Up Projects

Start with simple projects before tackling more complex designs; practice makes perfect!

5: Troubleshooting Common Issues During Arc Welding

Every welder faces challenges—understanding how to troubleshoot can save time:

- Poor penetration? Adjust your amperage. Excessive spatter? Check your gas flow rate.

FAQs about Arc Welding

1. What types of materials can I weld using arc techniques?

You can weld various metals including steel, aluminum, stainless steel, and even cast iron with suitable electrodes.

2. How do I know which type of arc welder I need?

Consider factors such as material thickness, type of metal being welded, and whether you'll be working indoors or outdoors when selecting equipment.

3. Is it necessary to have prior experience before attempting arc welding?

While prior experience can help, beginners can start learning under mentorship or through classes designed for novices in skills training centers.

4. What should I do if I feel unsafe while welding?

Stop immediately! Assess your environment—ensure correct PPE usage—and rectify any hazards before resuming work.

5. How often should I maintain my equipment?

Regular maintenance checks are recommended every few months; however, inspect equipment before each use for any visible damage or issues needing immediate attention!

6. Can mobile services provide all types of welds?

Most mobile welders are equipped for various types including SMAW, GMAW/MIG & GTAW/TIG depending on their specialization!

Conclusion

In summary, "A Complete Guide to Arc Welding for New Welders" provides you with valuable insights into this fascinating trade—from understanding basic safety protocols all the way through specialized techniques like plasma welding! With diligence in practice along with respect toward safety measures coupled with knowledge gained here today—you'll find yourself well-equipped on this rewarding journey into the world of metal fabrication service! Whether you're considering mobile solutions like those found across Phoenix or honing skills at home—every step counts! Now go ahead—ignite that passion within you because there's no better time than now! Happy welding!

This detailed guide serves as both an introductory manual for beginners as well as a reference point throughout one's ongoing journey into mastering the craft—a must-have resource indeed!